Product center

Product Center

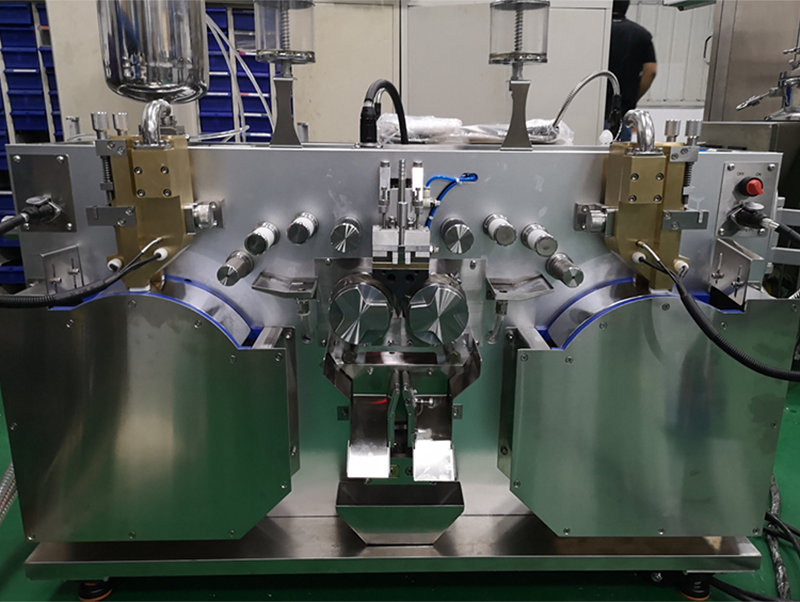

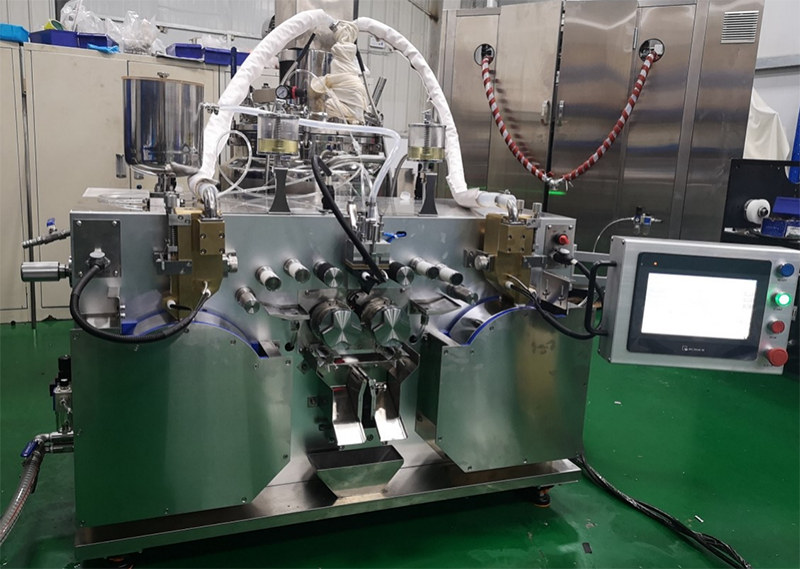

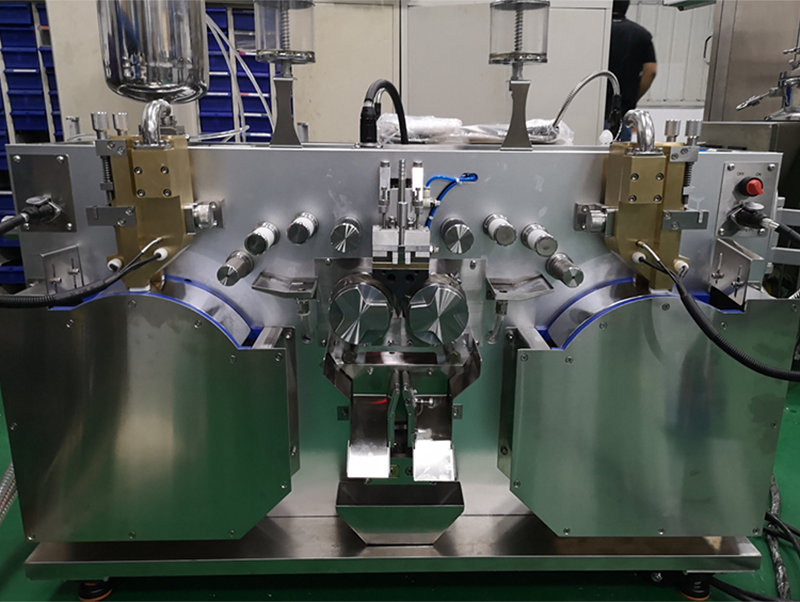

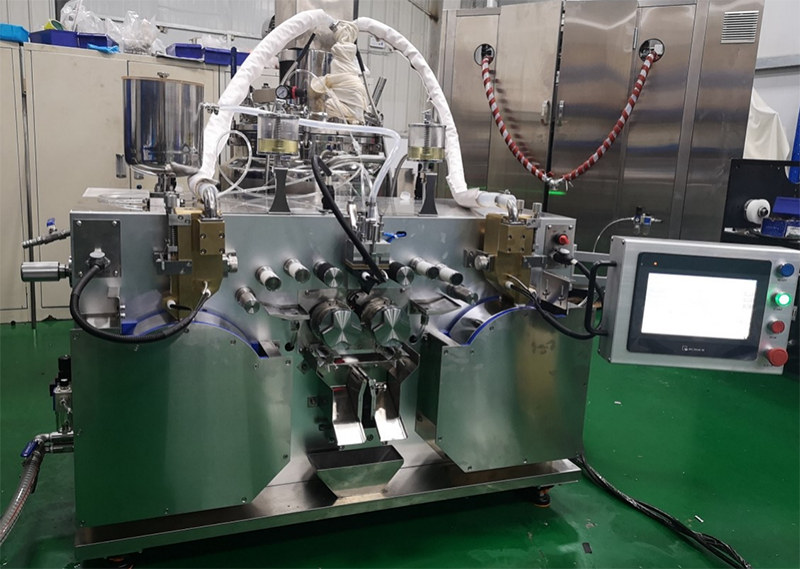

Model TS-1 Table Top Softgel Encapsulation Machine is designed by Beijing Summit Pharmatech Co., Ltd. according to customer's needs, specifically for laboratories of pharmaceutical and health product factories, CROs, CDMOs, food and drug research enterprises, university laboratories, hospital medicine departments, etc. This desktop softgel encapsulation machine (desktop soft capsule machine or tabletop soft capsule machine) maybe the smallest in the market.

This machine has a small footprint, low die roll cost, and low raw material consumption. It only requires 5L of gelatin and around 100ml of liquid medicine to conduct softgel capsule encapsulation tests. The machine is designed to run at single-phase 220V , making it convenient for users to conduct softgel capsule encapsulation tests under laboratory conditions.

This machine is suitable for testing soft capsule content and shell formulations, allowing for the production of required soft capsules at a lower cost. It is also suitable for designing and testing special-shaped die rolls (softgel molds) for softgel capsules.

1.TS-1 Small Softgel Macine Technical Parameters

✮Die roll size: φ104x50mm

✮Die roll speed:0~5rpm

✮Number of plungers: 2

✮Power: single-phase 220V,2kW

✮Size:1230x750x980mm

Weight:~400kg

✮Control method:PLC+Touch screen

2.Main features

Small and exquisite, covering an area of only about 1.5 square meters

No need to change the time gear when replacing the mold

Single-phase AC power is convenient for use in pharmaceutical factories, school laboratories and hospital preparation rooms

Save the liquid medicine, and you can trial-produce it on the machine with at least the medicine of one paper cup.

Save gelatin

Touch screen control, easy to operate

Opening and closing electric control cabinet makes it easy to repair and maintain

Capacity:

3OV

2 x 28 = 56 1RPM x 60 x 56 = 3360 pcs/hour

2 x 28 = 56 5RPM x 60 x 56 = 16800 pcs/hour

6OV

2 x 24 = 48. 1RPM x 60 x 48 = 2880 pcs/hour

2 x 24 = 48 5RPM x 60 x 48 = 14400 pcs/hour

10OV

1 x 23 = 23 1RPM x 60 x 23 = 1380 pcs/hour

1 x 23 = 23 5RPM x 60 x 23 = 6900 pcs/hour

12OB

1 x 25 = 25. 1RPM x 60 x 25 = 1500 pcs/hour

1 x 25 = 25 5RPM x 60 x 25 = 7500 pcs/hour

Model TS-1 Table Top Softgel Encapsulation Machine is designed by Beijing Summit Pharmatech Co., Ltd. according to customer's needs, specifically for laboratories of pharmaceutical and health product factories, CROs, CDMOs, food and drug research enterprises, university laboratories, hospital medicine departments, etc. This desktop softgel encapsulation machine (desktop soft capsule machine or tabletop soft capsule machine) maybe the smallest in the market.

This machine has a small footprint, low die roll cost, and low raw material consumption. It only requires 5L of gelatin and around 100ml of liquid medicine to conduct softgel capsule encapsulation tests. The machine is designed to run at single-phase 220V , making it convenient for users to conduct softgel capsule encapsulation tests under laboratory conditions.

This machine is suitable for testing soft capsule content and shell formulations, allowing for the production of required soft capsules at a lower cost. It is also suitable for designing and testing special-shaped die rolls (softgel molds) for softgel capsules.

1.TS-1 Small Softgel Macine Technical Parameters

✮Die roll size: φ104x50mm

✮Die roll speed:0~5rpm

✮Number of plungers: 2

✮Power: single-phase 220V,2kW

✮Size:1230x750x980mm

Weight:~400kg

✮Control method:PLC+Touch screen

2.Main features

Small and exquisite, covering an area of only about 1.5 square meters

No need to change the time gear when replacing the mold

Single-phase AC power is convenient for use in pharmaceutical factories, school laboratories and hospital preparation rooms

Save the liquid medicine, and you can trial-produce it on the machine with at least the medicine of one paper cup.

Save gelatin

Touch screen control, easy to operate

Opening and closing electric control cabinet makes it easy to repair and maintain

Capacity:

3OV

2 x 28 = 56 1RPM x 60 x 56 = 3360 pcs/hour

2 x 28 = 56 5RPM x 60 x 56 = 16800 pcs/hour

6OV

2 x 24 = 48. 1RPM x 60 x 48 = 2880 pcs/hour

2 x 24 = 48 5RPM x 60 x 48 = 14400 pcs/hour

10OV

1 x 23 = 23 1RPM x 60 x 23 = 1380 pcs/hour

1 x 23 = 23 5RPM x 60 x 23 = 6900 pcs/hour

12OB

1 x 25 = 25. 1RPM x 60 x 25 = 1500 pcs/hour

1 x 25 = 25 5RPM x 60 x 25 = 7500 pcs/hour

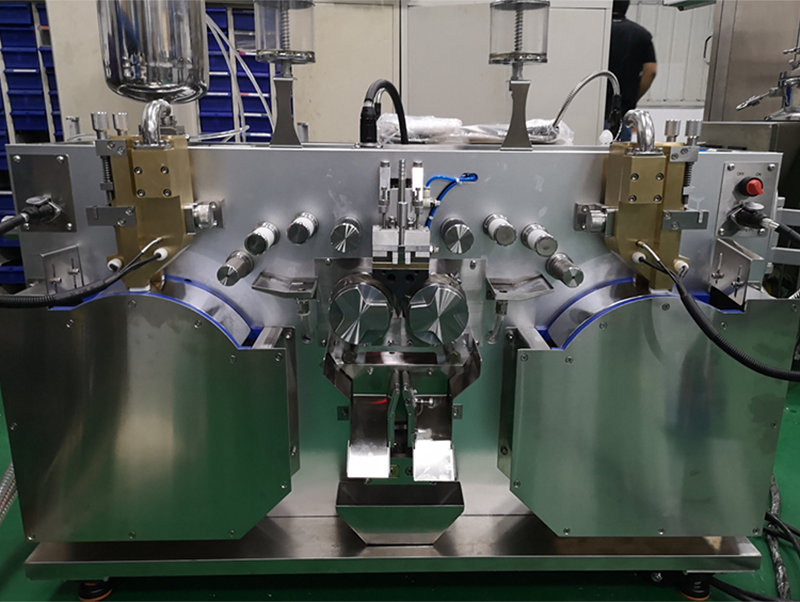

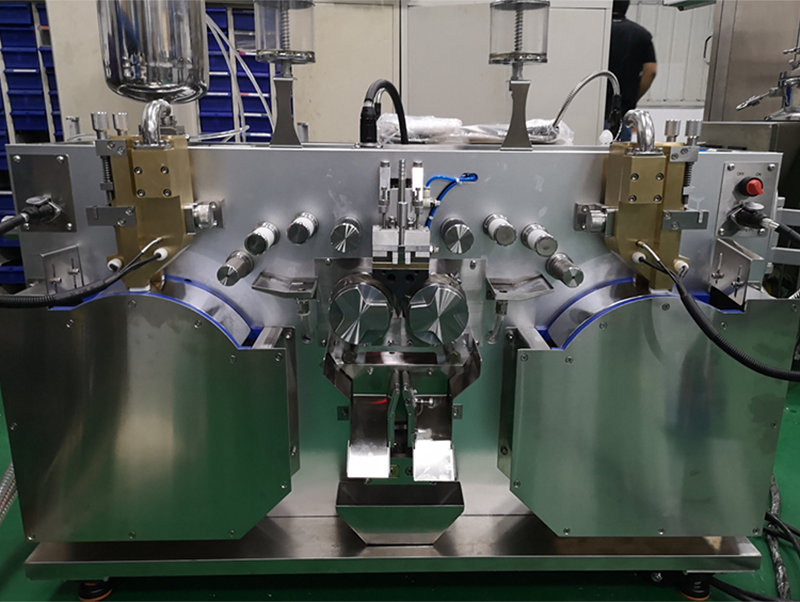

Model TS-1 Table Top Softgel Encapsulation Machine is designed by Beijing Summit Pharmatech Co., Ltd. according to customer's needs, specifically for laboratories of pharmaceutical and health product factories, CROs, CDMOs, food and drug research enterprises, university laboratories, hospital medicine departments, etc. This desktop softgel encapsulation machine (desktop soft capsule machine or tabletop soft capsule machine) maybe the smallest in the market.

This machine has a small footprint, low die roll cost, and low raw material consumption. It only requires 5L of gelatin and around 100ml of liquid medicine to conduct softgel capsule encapsulation tests. The machine is designed to run at single-phase 220V , making it convenient for users to conduct softgel capsule encapsulation tests under laboratory conditions.

This machine is suitable for testing soft capsule content and shell formulations, allowing for the production of required soft capsules at a lower cost. It is also suitable for designing and testing special-shaped die rolls (softgel molds) for softgel capsules.

1.TS-1 Small Softgel Macine Technical Parameters

✮Die roll size: φ104x50mm

✮Die roll speed:0~5rpm

✮Number of plungers: 2

✮Power: single-phase 220V,2kW

✮Size:1230x750x980mm

Weight:~400kg

✮Control method:PLC+Touch screen

2.Main features

Small and exquisite, covering an area of only about 1.5 square meters

No need to change the time gear when replacing the mold

Single-phase AC power is convenient for use in pharmaceutical factories, school laboratories and hospital preparation rooms

Save the liquid medicine, and you can trial-produce it on the machine with at least the medicine of one paper cup.

Save gelatin

Touch screen control, easy to operate

Opening and closing electric control cabinet makes it easy to repair and maintain

Capacity:

3OV

2 x 28 = 56 1RPM x 60 x 56 = 3360 pcs/hour

2 x 28 = 56 5RPM x 60 x 56 = 16800 pcs/hour

6OV

2 x 24 = 48. 1RPM x 60 x 48 = 2880 pcs/hour

2 x 24 = 48 5RPM x 60 x 48 = 14400 pcs/hour

10OV

1 x 23 = 23 1RPM x 60 x 23 = 1380 pcs/hour

1 x 23 = 23 5RPM x 60 x 23 = 6900 pcs/hour

12OB

1 x 25 = 25. 1RPM x 60 x 25 = 1500 pcs/hour

1 x 25 = 25 5RPM x 60 x 25 = 7500 pcs/hour

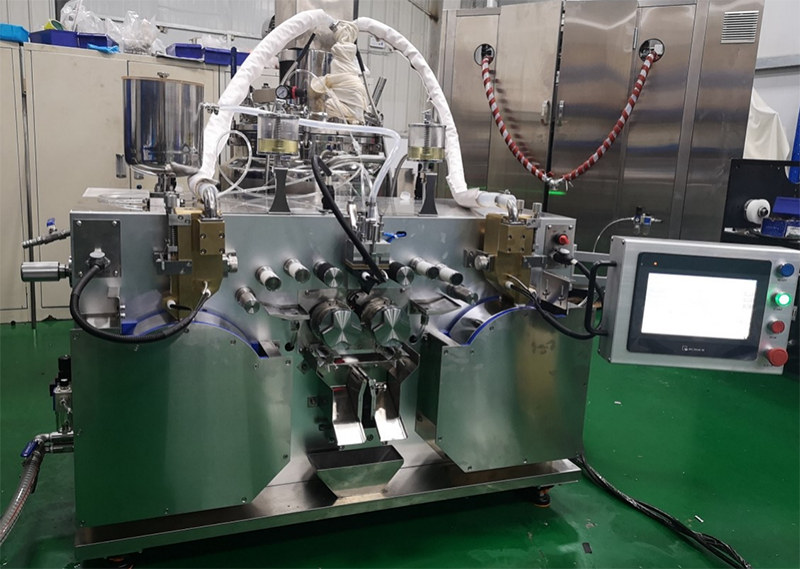

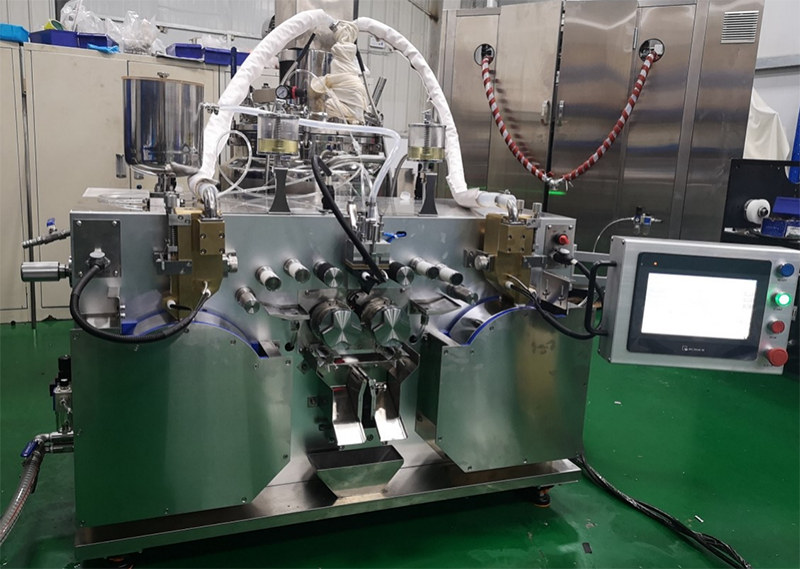

Model TS-1 Table Top Softgel Encapsulation Machine is designed by Beijing Summit Pharmatech Co., Ltd. according to customer's needs, specifically for laboratories of pharmaceutical and health product factories, CROs, CDMOs, food and drug research enterprises, university laboratories, hospital medicine departments, etc. This desktop softgel encapsulation machine (desktop soft capsule machine or tabletop soft capsule machine) maybe the smallest in the market.

This machine has a small footprint, low die roll cost, and low raw material consumption. It only requires 5L of gelatin and around 100ml of liquid medicine to conduct softgel capsule encapsulation tests. The machine is designed to run at single-phase 220V , making it convenient for users to conduct softgel capsule encapsulation tests under laboratory conditions.

This machine is suitable for testing soft capsule content and shell formulations, allowing for the production of required soft capsules at a lower cost. It is also suitable for designing and testing special-shaped die rolls (softgel molds) for softgel capsules.

1.TS-1 Small Softgel Macine Technical Parameters

✮Die roll size: φ104x50mm

✮Die roll speed:0~5rpm

✮Number of plungers: 2

✮Power: single-phase 220V,2kW

✮Size:1230x750x980mm

Weight:~400kg

✮Control method:PLC+Touch screen

2.Main features

Small and exquisite, covering an area of only about 1.5 square meters

No need to change the time gear when replacing the mold

Single-phase AC power is convenient for use in pharmaceutical factories, school laboratories and hospital preparation rooms

Save the liquid medicine, and you can trial-produce it on the machine with at least the medicine of one paper cup.

Save gelatin

Touch screen control, easy to operate

Opening and closing electric control cabinet makes it easy to repair and maintain

Capacity:

3OV

2 x 28 = 56 1RPM x 60 x 56 = 3360 pcs/hour

2 x 28 = 56 5RPM x 60 x 56 = 16800 pcs/hour

6OV

2 x 24 = 48. 1RPM x 60 x 48 = 2880 pcs/hour

2 x 24 = 48 5RPM x 60 x 48 = 14400 pcs/hour

10OV

1 x 23 = 23 1RPM x 60 x 23 = 1380 pcs/hour

1 x 23 = 23 5RPM x 60 x 23 = 6900 pcs/hour

12OB

1 x 25 = 25. 1RPM x 60 x 25 = 1500 pcs/hour

1 x 25 = 25 5RPM x 60 x 25 = 7500 pcs/hour